Wednesday, April 3, 2019

Tuesday, February 2, 2010

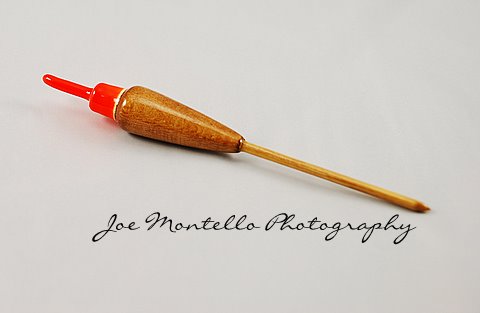

Steelhead Alley Floats

To purchase any Tackle or Floats please contact me at the email address listed below

I have Steelheader packs available at this time they are $30.00 a pack ( 5 Floats to a pack ) + Tax and Shipping , there is a variety of float sizes great for fishing single Salmon egg's , Jig & Maggot , Skien and Sacks . ( Packs my vary in stain color and size ) all depends on what size I have turned lately and what stain color I used ,I can email a picture of your pack prior to shipping ....Thanks !!! e-mail if you have any questions mailto:FishOnFloats@gmail.com .

Sucker Spawn Flies...$10.68 a dozen + Tax and Shipping , These flies work VERY WELL in the Tribs along Steelhead Alley , if you dont see a color you need just e-mail me and I will see if I have it ....Thanks !!!

Glo Bobs lead peg weighted float , this is a popular float that I see being used all the time on the Steelhead Alley Tribs . I am now selling these floats by the bag for $17.00 +Tax and Shipping .

Glo Bobs lead peg weighted float , this is a popular float that I see being used all the time on the Steelhead Alley Tribs . I am now selling these floats by the bag for $17.00 +Tax and Shipping .There are 24 floats in a bag .

Testimonials / Reviews

I just wanted to say that the floats you have made are the best floats that I have used. I find them to hold just enough shot that I use and have a very good flow to them and handles superb in any kind of water flow. And aslo found that they have very little friction in the water when fighting a Steelhead. Unlike the Sheffields and the Blackbird plastic floats that brake on contact of rocks or hard ice, I have not yet broke one of your floats due to I use Fireline as my my line. I use them on all my guides and would recommend anyone to use them over the store bought floats. Cant wait to test them out crappie fishing.

And again, surperb floats Joe!

Thanks.

Rob Beverly

Robs Guide Service

Joe Montello makes some of the best floats I have ever fished with. By using his craftsmanship and skill, Joe has produced many floats that track well, are very sensitive and they sustain through the conditions of the Great Lakes fishery. Joe's floats are also very easy to see which helps when making the perfect long distance drifts that many steelhead fisherman are in pursuit of. I recommend giving Joe's floats a try. You will not be disappointed.

Sal Saia

I've had the good fortune to not only fish Joe's floats for over 2 years, but also watch him 'burning balsa', as we like to say. All I can say is his craftsmanship and attention to detail are superb and the end result is the finest float money can buy. I fished one float for darn near 6 months. It ended up in trees, was stepped on and bounced off a few bridge pylons and still tracked flawlessly. Joe's floats perform beautifully and are practically bomb-proof.

Sincerely,

Steve D.

Absolutely the best floats Ive come across on the market today. Thanks Joe for making quality floats in every size I need for steelhead alley rivers & tribs.

tightlines to you!

Randy,(Magoo)

I would like to thank Joe at Fish On Floats for producing a truely remarkable float. Using other brands of floats for different styles of fishing, I was presented with a pack of floats from Joe and all I can say is WOW! They track well in river conditions and are bouyant enough for any shotting pattern as the different shapes and styles allow for varying conditions. They also work well for pond, lake and im impressed with them through the ice. Very well made, durable, and looks excellent. Will be looking forward to new styles in the future and now is my float of choice!.

Chris Furlong

I just wanted to say that the floats you have made are the best floats that I have used. I find them to hold just enough shot that I use and have a very good flow to them and handles superb in any kind of water flow. And aslo found that they have very little friction in the water when fighting a Steelhead. Unlike the Sheffields and the Blackbird plastic floats that brake on contact of rocks or hard ice, I have not yet broke one of your floats due to I use Fireline as my my line. I use them on all my guides and would recommend anyone to use them over the store bought floats. Cant wait to test them out crappie fishing.

And again, surperb floats Joe!

Thanks.

Rob Beverly

Robs Guide Service

Joe Montello makes some of the best floats I have ever fished with. By using his craftsmanship and skill, Joe has produced many floats that track well, are very sensitive and they sustain through the conditions of the Great Lakes fishery. Joe's floats are also very easy to see which helps when making the perfect long distance drifts that many steelhead fisherman are in pursuit of. I recommend giving Joe's floats a try. You will not be disappointed.

Sal Saia

I've had the good fortune to not only fish Joe's floats for over 2 years, but also watch him 'burning balsa', as we like to say. All I can say is his craftsmanship and attention to detail are superb and the end result is the finest float money can buy. I fished one float for darn near 6 months. It ended up in trees, was stepped on and bounced off a few bridge pylons and still tracked flawlessly. Joe's floats perform beautifully and are practically bomb-proof.

Sincerely,

Steve D.

Absolutely the best floats Ive come across on the market today. Thanks Joe for making quality floats in every size I need for steelhead alley rivers & tribs.

tightlines to you!

Randy,(Magoo)

I would like to thank Joe at Fish On Floats for producing a truely remarkable float. Using other brands of floats for different styles of fishing, I was presented with a pack of floats from Joe and all I can say is WOW! They track well in river conditions and are bouyant enough for any shotting pattern as the different shapes and styles allow for varying conditions. They also work well for pond, lake and im impressed with them through the ice. Very well made, durable, and looks excellent. Will be looking forward to new styles in the future and now is my float of choice!.

Chris Furlong

Wednesday, November 4, 2009

Subscribe to:

Posts (Atom)